capability

- Home

- capability

- Compression Molding

Compression Molding

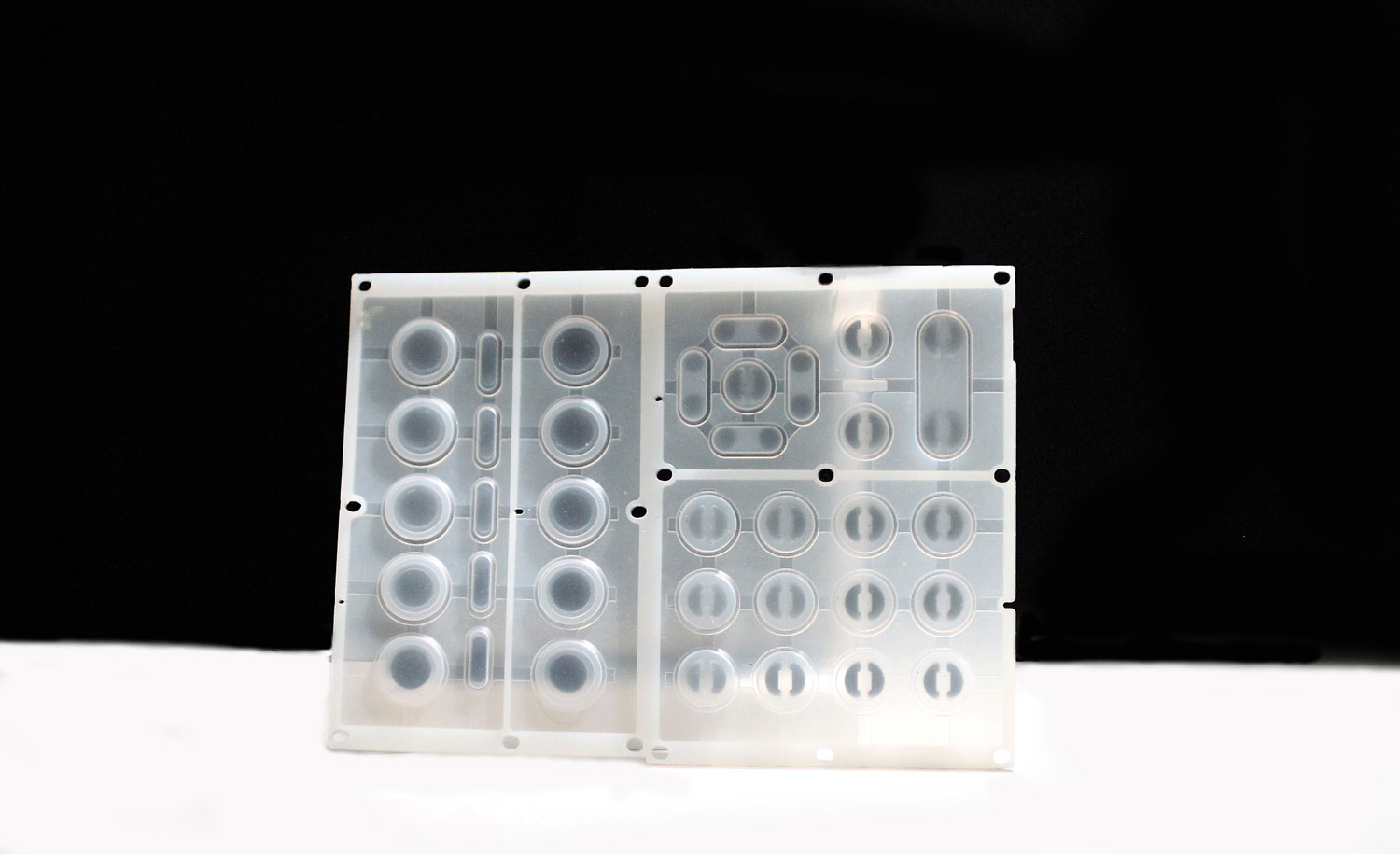

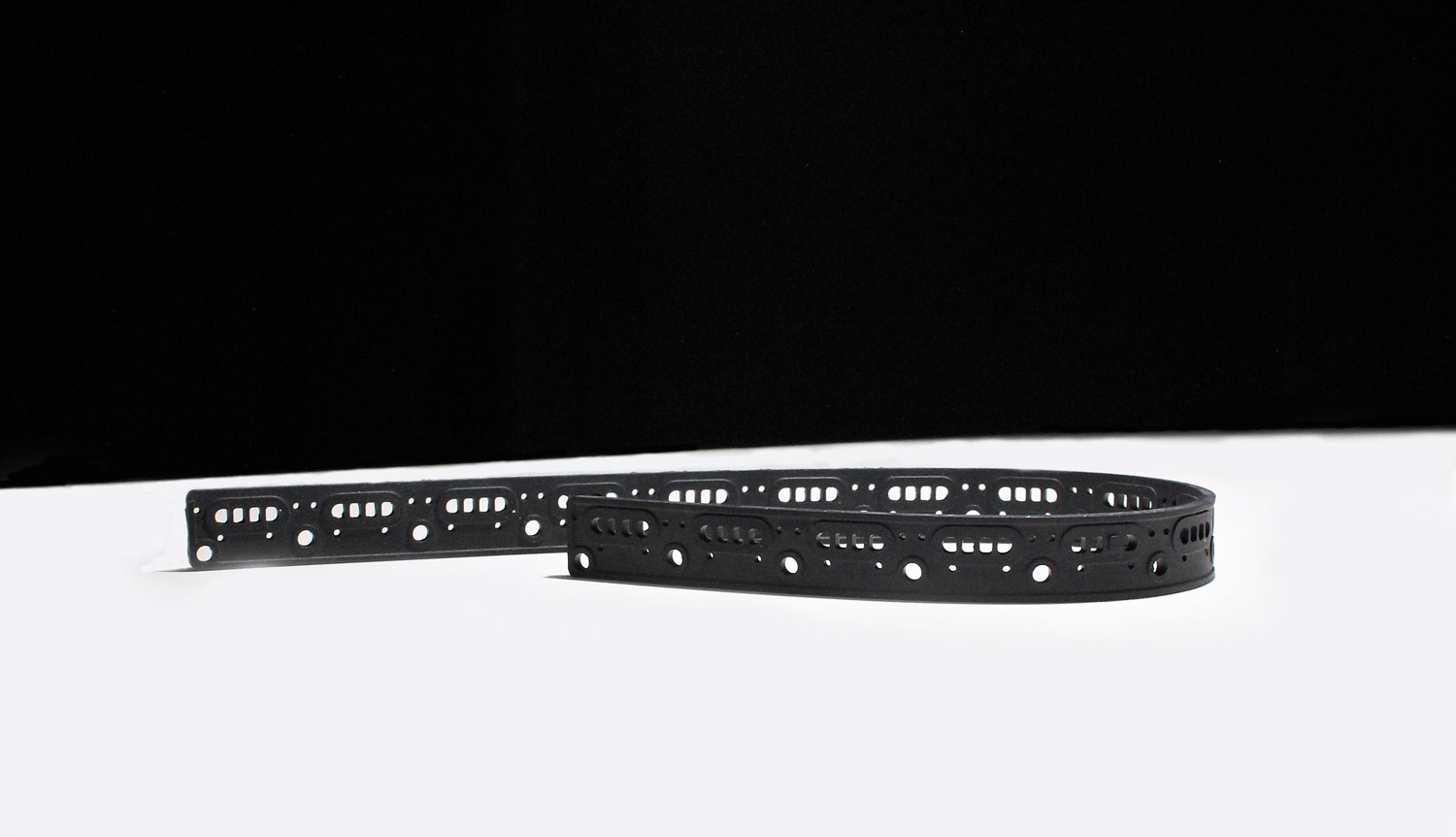

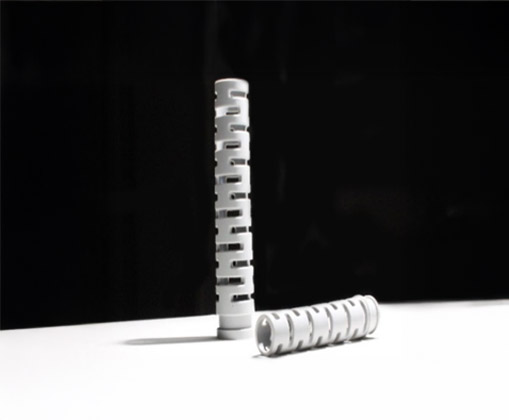

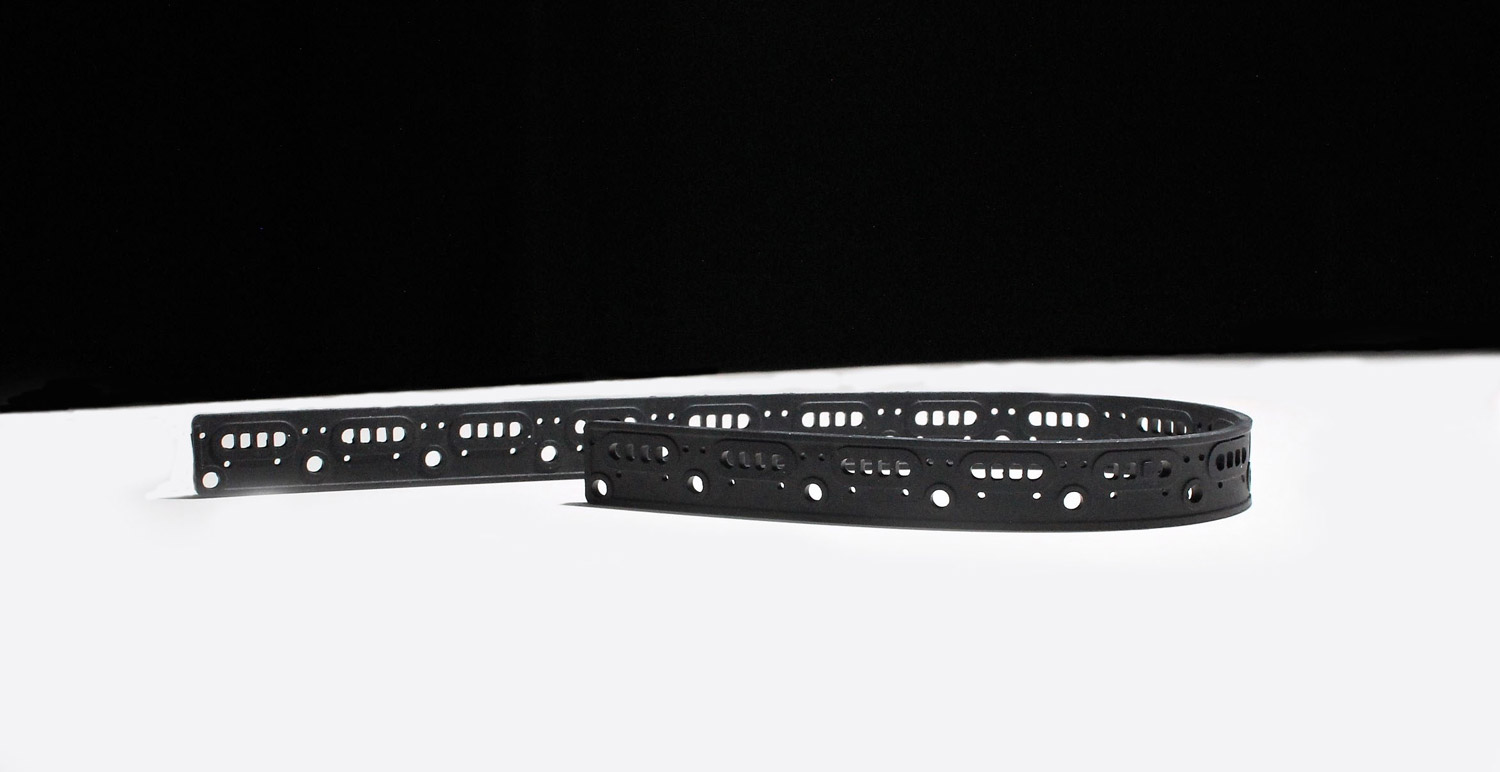

Compression Molding For Durable Rubber, Silicone, And Composite Parts. Provides Superior Resistance To Wear And Environmental Stress.

→ Ideal For Gaskets, Vibration Dampers, And Industrial-Grade Components.

Applications: Gaskets, Medical Pads, Insulation

Material - Manufacturers, Hardness

LSR (Liquid Silicone Rubber) : KCC, Shinetsu (10 ~ 90A)

HCR (High Consistency Silicone Rubber) : KCC, Shinetsu, Dow Corning (10~90A)

Medical Silicone : ISO10993, USP Class VI (40~70A), Nusil (Wacker), Dow Coring

Fluor Silicone : Shinetsu (20~80A)

NBR ((Acrylo)Nitrile Butadiene Rubber) : Kumho Petrochemical (40~90A)

EPDM (Ethylene Propylene Diene Monomer) : KUMHO POLYCHEM (40A~90A)

NR (Natural Rubber) : SP Chemical (40~90A)

SBR (Styrene Butadiene Rubber) : SP Chemical (40~90A)

CR (Chloroprene Rubber) : SP Chemical (40~90A)

H-NBR (Hydrogenated-Nitrile Butadiene Rubber) : SP Chemical (50~90A)

PU (Poly Urethane) : SP Chemical (60~90A)

Medical Silicone, Fluor Silicone : MOQ 20Kg

Quick Turn(Mobile Phone Size)

-

Simple

5-6 Day

-

Normal

8 Day

-

Complex

11 Day

Mix. Size & Color

Max. Size : 550X900x400mm

Pantone Color Code Or Chip Is Mandatory

NBR/EPDM - MOQ 100Kg And All Others Will Be

10Kg NBR Clear Is Not Feasible For Coloring

Life Cycle Time

Tool Material : 1.5K (S45C)

Mass Production : 200K (P20)

example image